自動化控制生產線

發布時間:2022-06-14

瀏覽次數:36

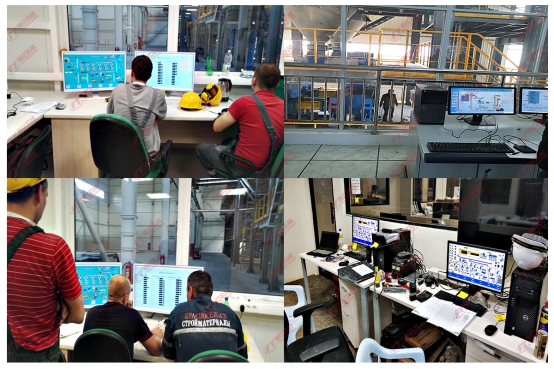

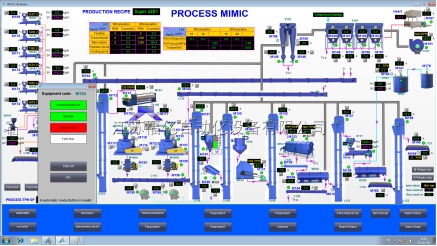

一、自動化控制系統簡介Introduction of automatic control system包括控制系統部分、動力柜部分、現場執行機構(如電動機、電磁閥等),通過PLC完成控制,采用國際標準的Profibus或者TCP/IP方式進行通訊,控制系統通過上位機輸入指令,PLC將輸出指令發送到現場各設備,完成自動控制。

Including the central control system part, the power cabinet part, the on-site execution mechanism (such as motor, electromagnetic valve, etc.). Use international standards mudbus communication protocol for communication, the central control system input instruction through the PC , PLC will send the output command to the scene of each device, complete the automatic control.

本系統是利用上位機及工業控制器軟硬件互相組態實現生產高度自動化、智能化。可以穩定的保證生產有序、安全進行,對生產過程集中進行監測、操作與管理,提高生產效率、穩定產品質量及管理水平。

The system is realized by computer technology and industrial controller hardware and software configuration, and the production is highly automated and intelligent. It can ensure the production orderly and safely, monitor, operate and manage the production process, improve the production efficiency, stabilize the product quality and management level.

二、總體方案Overall scheme

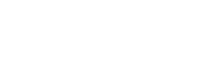

1. 系統組態框架示意(非實物)如下圖

The system is configured as follows (not the real):

自動化方案拓撲圖

Automation scheme topology

該系統分為監視層、通訊控制層、執行與數據采集層。監控層由人機界面系統組成;通訊控制層由西門子通訊總線、西門子PPI通訊和西門子PLC處理系統、標準協議及其介質、通訊線纜及轉換器組成;執行與檢測層分別是用來控制電機與傳感器數據采集等。

The system is divided into monitoring layer, communication control layer, execution and data acquisition layer. The monitoring layer is composed of man-machine interface system. communication control layer consists of Siemens communication bus, Siemens PPI communication and Siemens processing systems, standard protocols and media, communications cable and converter. The execution and detection layers are respectively used to control the data acquisition of motors and sensors.

本系統主要分為三部分組成:

This system is divided into three parts:

1)、包裝秤系統。Packaging scale system

2)、造粒系統。Granulation system

3)、除塵系統。Dust collection system

各部分功能層,自動化程序的控制下,以串口協議及PPI通訊協議作為聯通,實現以下功能:Each part of the function layer, under the control of automation program, uses serial port protocol and PPI communication protocol as Unicom to realize the following functions:

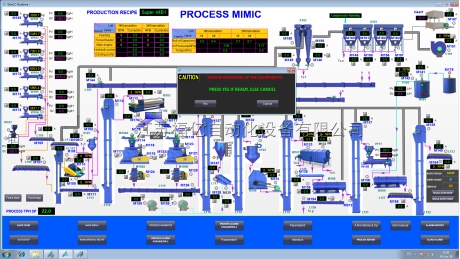

① 生產工藝、生產過程顯示及控制過程Production technology, production process display and control process

生產工藝、生產過程的顯示及控制,是自動化系統的基本人機功能,操作人員能夠通過人機界面,直觀的看到工藝進行的狀態,并對設備按照工藝的要求實施監控。直觀的看到設備的工作狀體,并做出異常判斷。

The display and control of the production process and production process are the basic functions of the automation system. The operator can visually see the status of processes through the man-machine interface, and also monitor the equipment in accordance with the requirements of the technology. Visually see the equipment working and make abnormality judgment.

西門子控制器編程語言:標準S7編程語言 LAD-Ladder Diagram。

Siemens controller programming languages: standard S7 programming languages LAD-Ladder Diagram

人機界面:KINGVIEW開發,基于VB、VC。

生產過程:根據工藝在人機界面上輸入相關的控制參數(主機造粒電流設定等),系統將根據相關參數控制除塵系統,給料擠壓主機等系統。

造粒主機電流控制:根據參數的設定,通過檢測主機內電流的大小,來控制與改變定量加料螺旋的速度,確保造粒主機電流恒定。The current control of the granulation host: according to the setting of the parameters, the speed of the spiral of quantitative feeding is controlled and changed by detecting the current in the host, so as to ensure that the current of the granulation host is constant.

② 自我診斷功能Self-diagnosis function

系統根據既定工藝,作好邏輯控制流程及備用控制,當某電機或工藝出現異常,系統會自動的診斷,在人機界面中做相關提醒,并執行合理的異常處理功能。

Systems in accordance with established process to improve the flow of control and backup control, when a section is abnormal, the system will automatically diagnoses, do the relevant reminder in the HMI, and implement a reasonable exception handling function.

③ 多級管理功能Multi-level management function

根據常規生產要求,系統設置2個管理權限層面,管理層及操作層,可以按照生產實際來啟用,不同的層面,具有不同的管理權限,管理層可以實現對整體的操作處理,而操作層只能實現對系統的基本運行操作管理。可以實現配方保密。

According to the conventional production requirements, the system set up two management authority level: management and operational levels, can be used in accordance with actual production. At different levels, with different management rights. Management level can be achieved on the whole operation process, but the operating level can only to achieve the basic operation management of the system . Formula secret can be achieved.

④ 其他個性化附加功能Historical data and print

該系統具有非常好的前瞻性柔化設計功能,可以根據客戶的實際生產需求,在控制系統允許的容量范圍內,增加個性化需求功能,系統設置3%的拓展余量。

The system has a very good forward-looking and flexible design function, which can increase the personalized demand function in the range of the allowed capacity of the control system according to the actual production requirements of the customer, and set up the expansion allowance of 3%.

⑤ 通訊支持及拓展Communication support and expand

S7/C7通訊對象間的通訊服務通過集成在系統中的功能塊進行。可提供的通訊服務有:

帶PPI的S7標準通訊。

各種接口的通用性。

編程器和個人計算機。

SIMATIC S5/S7。

工業人機界面。

第三方的編程控制器。

Communication Services of S7 / C7 communication object in the system by integrating the function blocks. The communication services maybe have:

S7 standard communication with the PPI.

S7 Communication Industrial Ethernet.

Interoperability of various interfaces.

Programmers and personal computers.

SIMATIC S5 / S7.

Industrial PC.

Third-party programmable controller.

三、系統設計System design

根據工藝流程,自動化控制生產過程大致如下:

According to the technological process, the process of automatic control production is as follows:

第一步:通過上位機對系統的相關參數進行設定,如造粒主機電流的設定,電流過大報警設定,自動/單機模式等等;

First: The relevant parameters of the system can be set by the host computer, such as setting the current of the granulator, setting the current too high, setting the alarm, automatic / single mode, and so on.

第二步:啟動系統,如果是自動模式則可以通過上位機一鍵啟停,可編程控制器按照工藝流程順序啟動設備,同時在啟動前會先自檢相關設備的馬達是否有故障;如果是單機模式,則需要操作人員手動一一啟動設備。

Second: Starting system, if it is automatic mode, can be started by one key by the upper computer. The programmable controller can start the equipment according to the process sequence. At the same time, the motor will fail to check the motor of the related equipment before starting. If it is a single mode, the operator will need to start the equipment manually.

第三步:系統已進入生產階段,上位機實時監控各設備運行狀況,如電機電流,頻率等等

Third: The system has entered the production stage, and the host computer monitors the running status of each device in real time, such as motor current, frequency and so on.

第四步:具有相關報警功能及記錄,例如成品輸送機馬達出現故障,則系統會及

時的發出警報通知操作人員前去處理,同時自動關閉前道設備以防止堵料等二次故障。

Forth: With related alarm functions and records, such as the failure of the finished product conveyor motor, the system will alert the operator in time to notify the operator and automatically close the front equipment to prevent two faults such as plugging.

四、本方案的特點如下:Forth、The characteristics of this scheme are as follows:

※ 實現生產過程工藝流程化、數據化管理、智能化、喂料自動調節。To realize process flow, data management, intelligence and automatic feeding adjustment in production process.

※ 系統操作便捷、穩定,對人友好,并可促進安全生產,提高產品質量穩定性;The system is easy to operate, stable, friendly to people, and can promote safety production and improve product quality and stability.

※ 生產過程實時監控,管理;The production process is monitored and managed in real time.

※ 系統節能降耗,減少人力成本及勞動強度,提高生產效率;The system can save energy and reduce consumption, reduce labor cost and labor intensity, and increase production efficiency.

※ 保障操作及維修人員安全,穩定生產。Ensure the safety of operators and maintenance personnel, and stabilize production.